Before Implementation

Challenge

A Digital Upgrade for Existing Infrastructure

Solution

After Implementation

Results

Client Feedback

Products

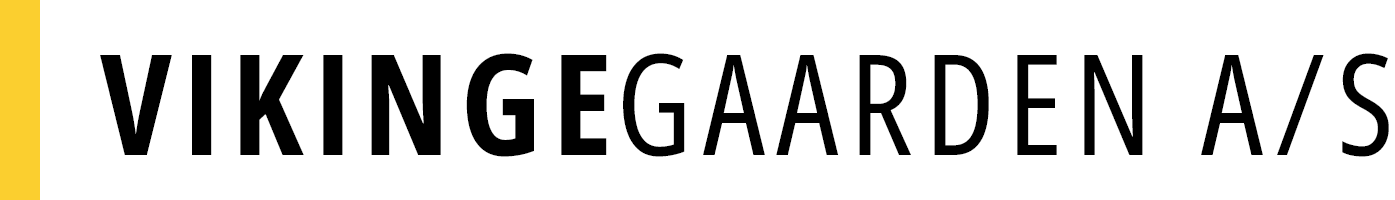

Marinella Neo

Smart power and water pedestal for marinas, supporting digital control, metering, and upgrading existing infrastructure.

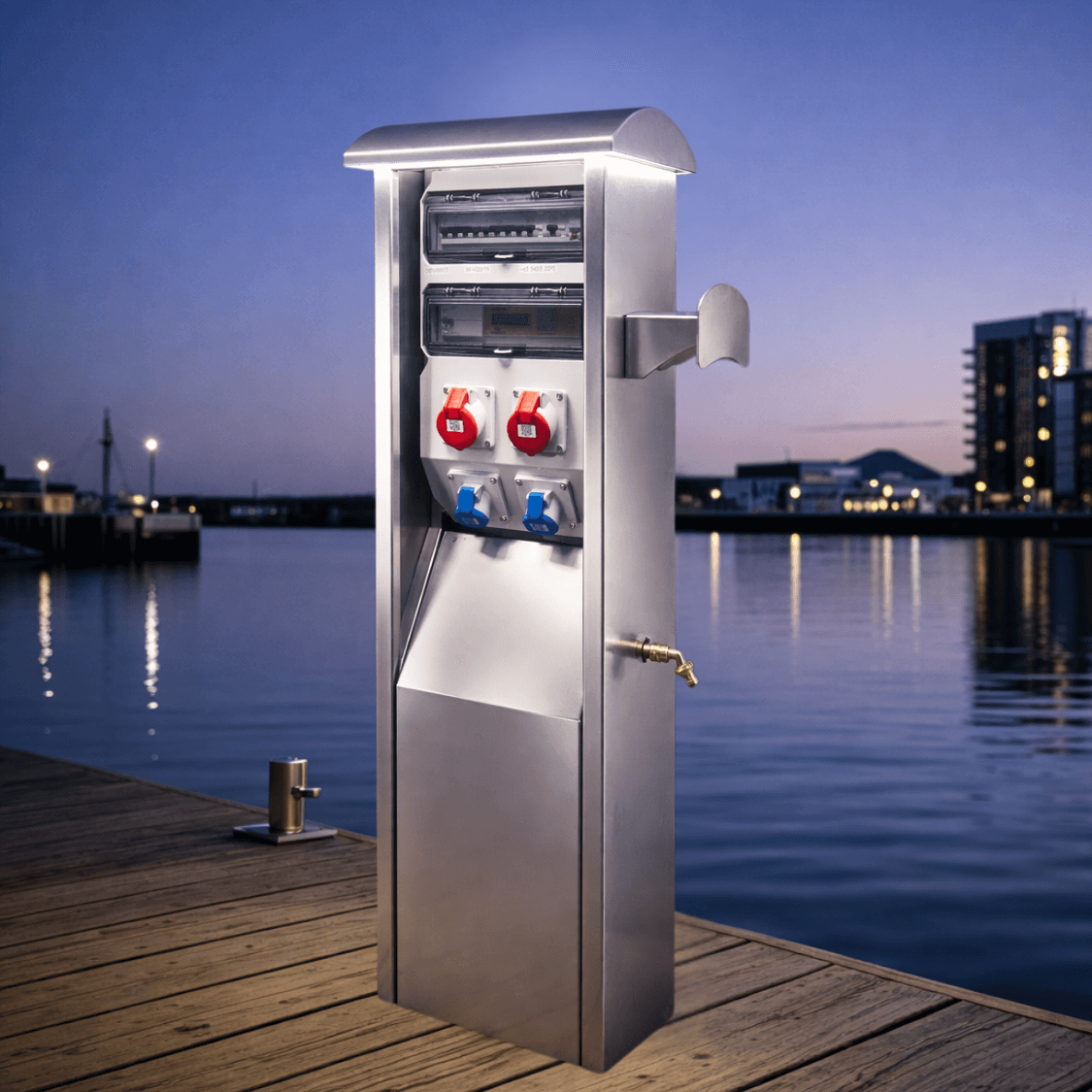

PowerGuard

Self-sustaining power supply solution with solar panel integration, grid-free operation, and backup power for remote locations.

MarineMax

Automated power supply with real-time Cloud monitoring and user-friendly operation.

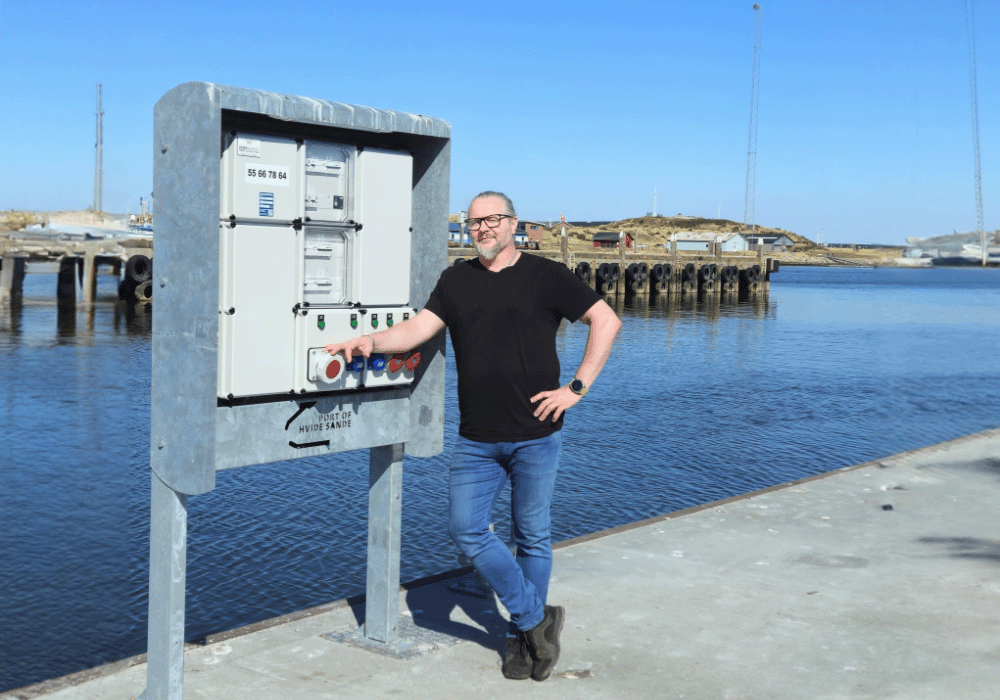

Marineium

Optimize maritime operations with our advanced port Marineium service pedestals, ensuring safety and efficiency in port management.

WaterStation

Self-service system enabling 24/7 water access with an automatic consumption tracker and Cloud-based data access for customers or personal use.

MarinePro

Automated power supply with real-time Cloud monitoring and user-friendly operation.

Marinella

Smart and durable supply stands equipped with sockets, water outlets , EV charging ports and online payment systems.